Stories

Arnold Treister

1925-

When Arnold Treister left Wellington College in 1941, he joined the family firm. "I never thought of doing anything else," he says. "Making hats was in my DNA."

Treister Hats, one of the country’s main mass manufacturers of men’s and women’s headwear for over 60 years, was founded by Arnold’s father Samuel in 1914. Russians of Jewish origin, Samuel Treister and his wife Mary migrated to New Zealand via England where he learned to make men’s hats and caps. By the time the Treisters arrived in Wellington in 1912, Samuel was proficient in the trade.

In a stair lobby space, loaned to him by his brother-in-law (a tailor), in a building on Lambton Quay, Samuel commenced manufacturing. He became a cap and children’s sun-helmet supplier to Dunedin warehousemen and clothing manufacturers Sargood, Son & Ewen. Simultaneously, he made traditional men’s felt hats, stitched from cut patterns, for other customers.

To accommodate the expanding business, new premises were found in Vivian Street and a proper manufacturing workroom with machinists was set up. As the hat was a part of the male uniform - all classes, from professional men to manual workers, wore hats at that time - Samuel’s hats found a ready market. He travelled the country forging relationships with retailers. "All the major department stores had menswear departments and they all sold hats," Arnold explains, "as did the specialty menswear stores."

Samuel was later joined in the company by his second daughter Vera and his first son Joel who volunteered for war service in 1940 and lost his life in the Battle of Britain.

During World War II, Treister Hats was classified as an 'essential industry'. It was contracted to make hats for most of the armed services. These included the WAACs (Women’s Auxiliary Army Corps), the WAAFs (Women’s Auxiliary Air Force), the nursing corps and the army. An outstanding example of their war-time production is the iconic 'lemon-squeezer' hat, first worn by soldiers in World War I, so-named because of its distinctive high crown with deep indentations on all four sides, and said to simulate Mt Egmont.

The company’s acquisition of a special multi-fingered machine, which simplified the production of the 'lemon-squeezer', came about by accident when Vera, instructed by Samuel to order a pamphlet giving details of the machine, inadvertently ordered the machine instead. When it arrived, Vera was despatched to charm the bank manager into providing a loan to cover the considerable cost. The machine, presently in the possession of Hills Hats of Petone, is still used today in the manufacture of the 'lemon-squeezer', now worn as part of the New Zealand Army’s ceremonial dress uniform.

On the 1953/54 Royal Tour, Queen Elizabeth II inspected New Zealand soldiers wearing 'lemon squeezer' hats manufactured by Treister Hats.

From the age of 14, Arnold helped out in the factory during his school holidays. When he joined the company full-time during the war, he already had a knowledge of the hat trade. Following the tragic death of his parents in an air-accident near Rome in 1951, Arnold, his sister Vera and her husband took over the running of the business.

A short spell in Australia in the late 1940s, working for Henry and Egan, the Sydney arm of a major British headwear manufacturer specialising in women’s pre-stitched hats, aroused Arnold’s interest in the production of women’s headwear. On his return to Wellington, he introduced a women’s fashion range (the Arnold label) to complement the men’s lines which continued under the Treister name.

Farmers advertisement for Westminster tailored felt hats by Treister, Auckland Star, 1945.

One of Arnold’s main reasons for expanding into women’s hats was the dwindling demand for men’s headwear. In order to remain viable, the business had to diversify. Although men in certain age-groups continued to wear hats, they were no longer a social obligation. In the context of increased car ownership and more affordable air travel, they were also considered a hindrance. "Cars and planes," says Arnold, "were not hat-friendly."

With travel in mind, the company designed the Pocket Hat, a fold-up adaptation of a man’s brimmed hat. It came in a plastic pouch and could be pocketed for travelling. A portable option for women, the Pack-it Hat, made of fur felt with a handcrafted peachbloom finish, had a flexible brim and could be worn several different ways.

Advertisement for the Arnold Pack-it-Hat which was made in nine colours and black.

Treister Hats had a licensing arrangement with Christys’ of London, a leading maker of men’s headwear, to manufacture their hats in New Zealand. Christys’ managing director paid periodic visits and assisted Arnold with in-store promotions. A 1961 advertisement in The Evening Post reads: "The new Christys’ hat for men young, and young in heart, will be presented by Mr Chichester himself (Managing Director of Christys’ of London) at Vance Vivian’s Cuba St store next Friday. You will be able to ask the world’s foremost hat authority 'does this hat suit me?'"

Arnold describes his women’s hats as "everywoman" hats, the kind worn on a day-to-day basis, to town, to church, to work. He produced hundreds in each style and sold them throughout New Zealand in millinery salons and department stores such as James Smiths (Wellington), Smith & Caughey’s (Auckland), Ballantynes (Christchurch), The DIC (Dunedin), H & J Smith’s (Invercargill).

Fake fur hats in different styles were a mainstay of the Arnold ranges throughout the 1960s.

To anticipate trends, shapes, colours and trims for coming seasons, Arnold flew to Europe and England on a regular basis. He brought back samples and employed milliners to interpret the designs for the local market. During the period of import restrictions (1938-1982), he was able to obtain raw materials with the assistance of the New Zealand Textile & General Manufacturers Federation. Embellishments, on the other hand, such as flowers, feathers and other fancy trims, were harder to come by.

In the process of growing the business, Arnold gradually acquired other hat manufacturers who were folding and absorbed them into the company. These included National Hat Mills, Anita Millinery, Gregory Hats and Harris Hats of Napier.

An overnight fire in the Vivian Street factory in 1953, in which summer straw hats sprayed with an acetate stiffener went up in flames, precipitated the move to larger premises. A purpose-built hat factory was erected in Lower Hutt, where the firm already had a small unit set up for overflow work. The new factory provided employment for residents of Naenae, a nearby government housing area. It had a creche and flexible working hours.

Treister Hats factory Lower Hutt, 1970s. Employees who did not live locally were transported daily from Wellington in the comapny's VW Combi van.

Treister Hats maintained long-standing relationships with its employees, several of whom stayed with the company for 30 years or more. It also remained a family concern. Working alongside Arnold were his sister Vera, her husband Issey Dabscheck and another sister Rita who, together with her husband Harry Cook, managed a new cap factory the company set up in Christchurch in the 1970s. Arnold’s daughter Gael, her husband Uzi Keren and Vera’s daughter Suzanne also worked for the firm.

The advent of 'big' hair and a younger, more casual approach to fashion in the 1960s heralded tough times for the hat industry. A canny businessman, Arnold looked for, and took advantage of, opportunities outside the mainstream. When he discovered women in London and New York wearing Beatle wigs in natural hair colours, he acquired the long pile fur fabric they were made of and put the wigs into production here. "They sold like hot cakes," he says. "We made hundreds."

Similarly, when television series such as Dallas and movies like Indiana Jones created a demand for lookalike hats, Arnold was quick to see the potential. Indiana Jones’ felt fedora with turned-down brim, the western style hats worn by the J. R. Ewing character in Dallas, and the Australian golfer Greg Norman’s 'great white shark' hat all found their way into menswear stores throughout the country.

School uniform felts, Fred Dagg canvas cow-cocky hats, Annie Hall derbys and high-domed Courrèges-style air hostess hats (for Air New Zealand) were among the many other specialised items manufactured by the company over the years. Having the expertise and the equipment to produce such a wide variety of styles for both sexes made it possible for Treister Hats to stay in business longer than most of its competitors.

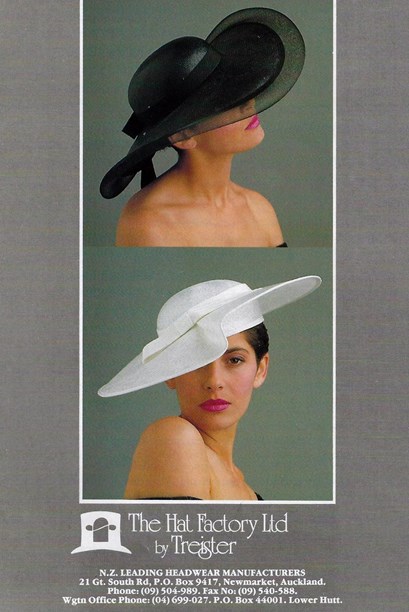

In 1987, Treister Hats joined forces with Auckland-based The Hat Factory. The new organisation, known as The Hat Factory by Treister, enabled rationalisation in manufacturing, administration, marketing and distribution. Initially production was spread between The Hat Factory’s plant in Auckland and the Treister plant in Lower Hutt but gradually the Hutt Valley operation was wound up.

The Hat Factory by Treister summer hat advertisement, 1988.

Arnold Treister retired from hat-making in the mid-1990s. Now 92, he says of his many years in the hat trade: "I loved it. It was a challenge all the way. Each time I met with success, it spurred me on."

Text by Cecilie Geary. Banner image of Arnold Treister (right) with National MP Lance Adams-Schneider, Treister Hats factory, Lower Hutt 1971. Image © Hutt City Libraries.

Last published May 2017.